Cleanrooms are essential controlled environments used in industries such as pharmaceuticals, biotechnology, and electronics manufacturing. Their primary purpose is to maintain high levels of cleanliness and minimize contamination, which is […]

Ultra Pure Water (UPW) is critical in industries where even the smallest impurities can have significant consequences. It is used in semiconductor manufacturing, pharmaceuticals, and high-end laboratories—applications that demand the […]

At Lighthouse Worldwide Solutions, we’re excited to introduce our latest innovation: the ActiveCount Remote Impactor Kit. This advanced system pairs the trusted performance of our ActiveCount25H or ActiveCount100H viable samplers […]

Liquid particle counting is essential for maintaining public health and safety by monitoring the purity and quality of liquids across various sectors, including drinking water, pharmaceuticals, and food production. This […]

It’s actually not as complicated as it might sound at first. Think of GAMP as your friendly neighborhood guide to making sure medicines are top-notch and safe for everyone. GAMP […]

In the world of cleanrooms, where the highest standards of cleanliness and contamination control are paramount, air filtration systems play a pivotal role. The evolution of these systems, especially with […]

The 2022 update of the EU GMP Annex 1 has placed significant emphasis on the concept of continuous environmental monitoring (EM), highlighting it as a critical component in reducing the […]

Compliance with USP 788 standards doesn’t have to be a complex and laborious process. Recent advancements in liquid sampling technology have made achieving USP 788 compliance both simple and effective. Liquid sampling […]

In the complex landscape of pharmaceutical manufacturing, where the safety and efficacy of medicinal products are paramount, Annex 1 of the EU Guidelines for Good Manufacturing Practice (GMP) for Medicinal […]

Your Contamination Control Strategy (CCS) is the foundation of your cleanroom. This is where you plan how to avoid contamination, what to do in the event there is a breach, […]

The European Union (EU) Good Manufacturing Practice (GMP) for Medicinal Products for Human and Veterinary Use – Annex 1, commonly referred to as GMP Annex 1, released a new update […]

In 2020, a vote found EN ISO 14698 no longer suitable for use in Europe, and, thus, it was replaced by EN 17141. Now, there is a push to accept […]

After 17 years of no revisions, a formal vote in 2019 replaced EN ISO 14698 with EN 17141 in Europe. Shortly after, confusion ensued. While CEN/TC243 (the technical committee in […]

EN 17141 Cleanrooms and controlled environments – Biocontamination control is a relatively new European standard, introduced in 2020, that establishes and demonstrates best practices to control airborne and surface microbiological […]

In 2017, GMP released a draft update to Annex 1, which received a lot of feedback. Now, GMP has released a finalized version of the updated Annex 1, which addresses […]

The European Union (EU) Good Manufacturing Practice (GMP) for Medicinal Products for Human and Veterinary Use – Annex 1, commonly referred to as GMP Annex 1, was originally published as […]

If you use compressed gasses in your cleanroom, ISO 8573 is an important set of guidelines and regulations for your cleanroom, specifically ISO 8573-1:2010. This set of guidelines is maintained […]

Good Automated Manufacturing Practices (GAMP). GAMP is both a technical subcommittee of the International Society for Pharmaceutical Engineering (ISPE) and a set of guidelines for manufacturers and users of automated […]

If you know us, then you know that clean air and water is our passion in life. But what happens when you cannot prove to the regulatory authorities that your […]

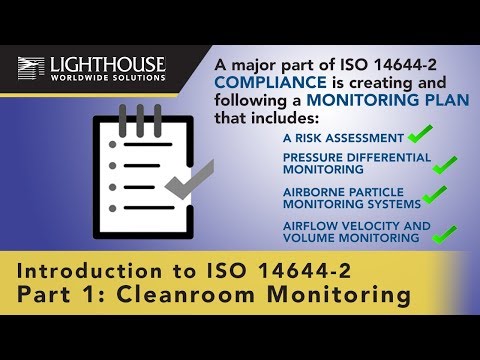

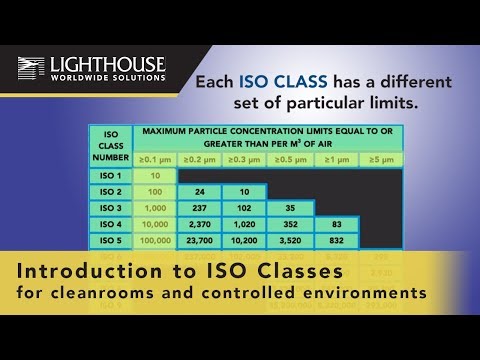

ISO 14644 is a standard for cleanrooms that was developed by the International Standards for Organization (ISO). The ISO has been in existence since 1947, after 65 delegates from 25 […]

What is the biggest villain in the contamination control and cleanroom world? Particles. Contamination. This contamination can cause yield and financial loss, delays, frustration, and physical threats to the end […]

The following questions will help you ask the right questions when implementing a system thatadheres to 21CFR Part 11. It is important to satisfy the requirements of this FDA code […]

21 CFR Part 11 outlines the federal requirements that help to ensure that electronic records are trustworthy, reliable, and generally equivalent to paper records and handwritten signatures executed on paper. […]

Water is one of the major utilities used by the pharmaceutical industry. Different grades of water quality are required depending on the different pharmaceutical uses. Control of the quality of […]

We are all too well aware of the adverse effects of particulate matter contamination within parenteral injectable pharmaceutical products and the consequences for patient safety. Here, particulate matter refers to […]

Good Manufacturing Practices (GMPs – sometimes referred to as Current Good Manufacturing Practices or CGMPs) are federal regulations set by the FDA to cover how pharmaceuticals and food products are manufactured. […]