It is no mystery that cleanrooms need to be, well, clean. From the surfaces and tools to the air in the cleanroom, everything needs to remain at a certain level of cleanliness depending on the cleanroom’s classification and application. Those criteria extend to the compressed gasses used in cleanrooms, as well, like oxygen, hydrogen, methane, nitrous oxide, etc.

These compressed gasses need to be sampled and monitored just like the air in your cleanroom. GMP requires this testing, as well as other regulatory bodies. For instance, ISO 8573 outlines requirements for air samplers or particle counters and the contamination values for the different classifications of cleanrooms.

When deciding what tool to use for gas sampling, you should first understand your needs and then the benefits presented by either a particle counter or an air sampler. Depending on your cleanroom’s classification and application, either tool presents a valid option.

Using Particle Counters For Gas Sampling

When using a particle counter for gas sampling, you will also need to use a High Pressure Diffuser (HPD). This is a tool that connects the gas line to the particle counter intake. It diffuses the compressed gas so as to prevent damage to the delicate sensor and laser diode. There are two primary types of HPDs: Vented Return HPDs and Ported Exhaust HPDs.

Which HPD you choose depends on the type of compressed gas you are using. Vented Return HPDs vents the gas back into the environment, whereas Ported Exhaust HPDs releases the air outside of the environment. This is useful for unsafe gasses, such as flammable ones if open flames are present in the environment.

The HPD does more than venting the gas and protecting the sensitive interior of the particle counter. It also ensures isokinetic sampling by decreasing the flowrate of the gas to match that of the particle counter. To verify the system is set up correctly and results are accurate, the flow rate should be the same through the HDP and the particle counter.

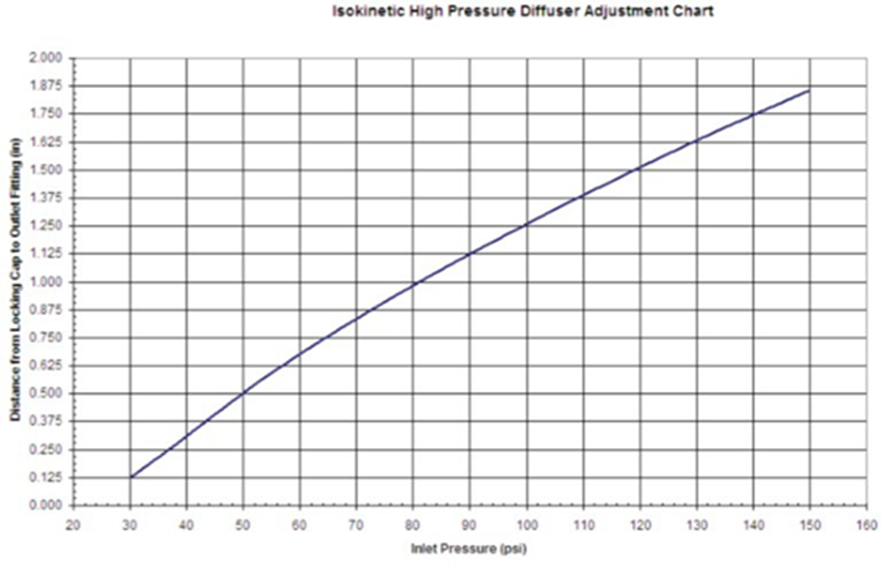

With the right pressure, the particle counter is able to sustain the right air flow. The table below outlines the correct HPD adaptor adjustment based on the inlet pressure of the compressed gas to be sampled to maintain ideal flow into the particle counter for accurate sampling.

Using Active Air Samplers For Gas Sampling

If you use the right Active Air Sampler, it can eliminate the need for attachments like an HDP. For example, the ActiveCount100H makes gas sampling a breeze.

You’ll want to simply start with a new Petri dish, free of agar. Once the fan is blowing, you’ll attach the gas sampler snugly to the sampling head. Next, you’ll simply adjust the flow rate to optimize it for gas sampling. The ActiveCount100H makes this simple to do with easy to read indicators. And just like that, you’re ready to start gas sampling!

Choosing Your Gas Sampling Equipment

Depending on your cleanroom’s application and classification, you’ll need to monitor for different sizes of particles. This will impact the equipment you should use. For many cleanrooms, portable particle counters are already in use and readily available, making for a multi-use tool and investment. Whether you choose to use an active air sampler or a portable particle counter, you should ensure you’re choosing a powerful, top-of-the-line, versatile tool with manufacturer support.

When choosing an active air sample, we recommend looking for the following attributes:

- Gas connector options for testing gasses to ISO 8573 requirements.

- Small physical size for ease of installation, movement, and handling.

- Preference towards stainless steel, but, in general, the material the sample head and enclosure is made of should be nonporous and easily sanitized.

- The active air sample should be easy to wipe down, without crevices, button switches, or particle traps.

- The media plate holder needs to be easily adjustable, with holder mechanism media dish diameters of +/- 1mm to 3mm.

- A HEPA filtered exhaust that captures viable particles which have not impacted.

- Touchscreen Interface that reduces contact and potential particle generation.

- For better portability, it should be battery operated.

- Remote sample options to offer more flexibility.

- Local or field calibration options from supplier.

- Easily autoclave parts.

- Capture particles down to 1um to meet ISO 14698 requirements.

- Validated for collection efficiency by a third party.

When looking for a particle counter, you should look for the following attributes:

- HPD adaptor options.

- Small size and portability for ease of use.

- Made of material that is easy to clean and sanitize while being free of particle traps.

- Self diagnostic tools to ensure you are aware when the particle counter stops working.

- Long battery life to allow for flexibility and less time recharging.

- Wireless connections and remote sampling capabilities.

- Adaptability to your current systems.

- Service Level Agreements with the manufacturer.

- Minimum of 0.3 – 10.0μ particle size channels for a variety of options.

- Sealed chemically compatible enclosure for protection of the laser diode and sensor during intense cleanroom cleaning.

- 21 CFR Part 11 compliant design.

- Customizable data report options to fit into your business.

- Easily adjustable SOPs and parameters.

Whether you decide to go with an active air sample or particle counter, we recommend working with an organization who has a lifetime track record of excellence and dedication to their client. This is done through comprehensive Service Level Agreements, warranties, performance qualifications, operational qualifications, and outstanding customer service.

Here at Lighthouse Worldwide Solutions, we recognize that is what separates an excellent experience in one of the largest, most important investments your organization will make from a subpar experience.

That is why we have dedicated ourselves to developing clean air technology that sets industry standards for over 40 years. Our particle counters and other equipment are designed to meet your known and unknown needs based on our experience in and our cleanrooms in a variety of industries: from pharmaceuticals to food processing to semiconductors.

If you’re ready to find the particle counter, active air sampler, or EMS that is right for your organization, contact us today for a hassle-free consultation.