So what exactly makes a cleanroom… A cleanroom? First and foremost, a cleanroom needs to be clean. You are able to communicate just how clean it is through its cleanroom classification.

But you cannot attain the classification without first making sure your cleanroom is really that clean. You do this through a proper cleanroom contamination control strategy and design.

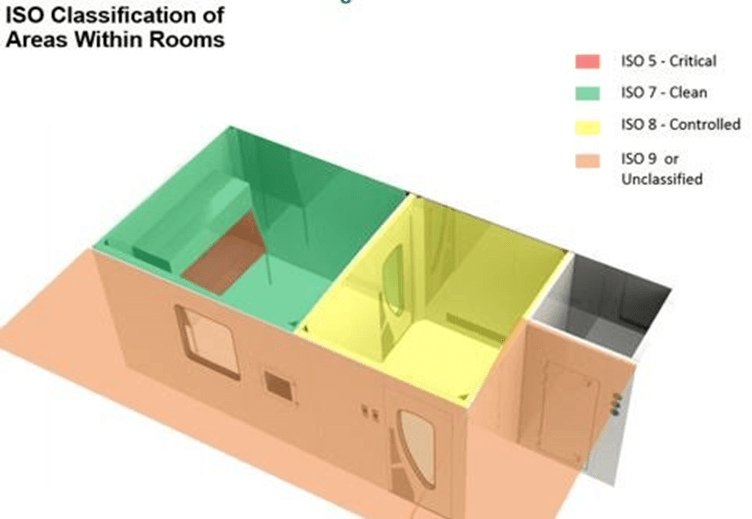

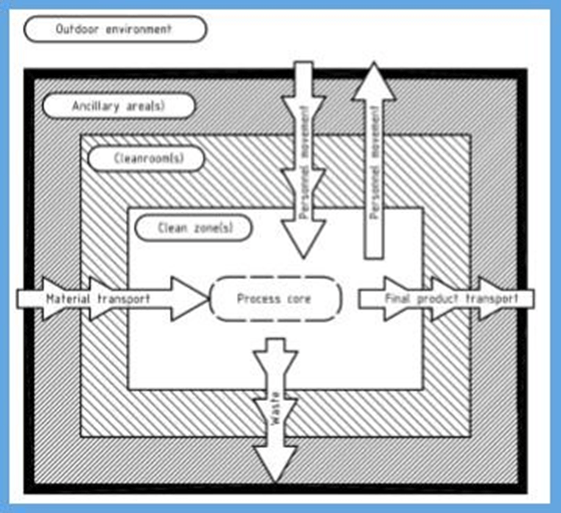

Whether your cleanroom is one room or a network of rooms connected by hallways, you need to pay attention to airflow. The only air that enters the space must come through the proper filters. Additionally, the temperature and humidity must be closely controlled. This is why Air Handling Units (AHUs) in cleanrooms normally consume at least 60% of its power usage.

Proper airflow ensures that clean, fresh air, as well as filtered, recirculated air, is used to constantly flush cleanrooms. This is often done through the strategic use of positive and negative pressure.

Essentially, a room with negative pressure has a lower air pressure than surrounding rooms and hallways. When a door is opened, air rushes in. This keeps particles and contaminants in the room, but can also introduce particles from the exterior corridor.

The reverse is true in a positive pressure room. When the door is opened, air rushes out. This pushes contaminants out of the room.

This physics phenomenon creates what we call “clean corridors” and “dirty corridors”. If air is rushed out into the corridor from a positive pressure room, the corridor is considered dirty. But the sensitive contents of the room are saved from contamination. As part of your cleanroom contamination control strategy, you should coordinate the clean and dirty corridors and the pressure in each area. When planning your doors, ensure they open towards the higher pressure area.

Beyond the structure around the air flow, you need to ensure that everything in your cleanroom is free of particle traps. This means everything should be built from non-porous, easily sanitized materials.

While this is all pivotal in keeping a cleanroom clean, why does it even matter? What are cleanrooms used for?

What Are Cleanrooms Used For?

Cleanrooms are used in a number of industries, such as manufacturing, pharmaceuticals, food production and packaging, and laboratory research. They are very versatile!

Essentially, cleanrooms are used when the contents of the room must be protected.

In manufacturing, this is because the end product is very sensitive to contamination. We commonly see this in technology. Products like semiconductors are so detailed that even the tiniest of particles can interrupt the user experience.

In other settings, like pharmaceuticals and food production, contamination can be harmful to the end-user. Thus, cleanrooms are critical to keep the product as contaminant-free as possible.

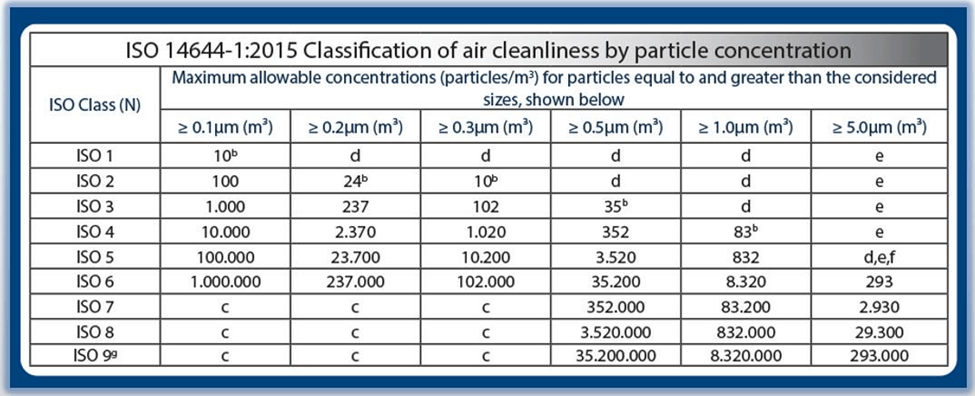

Depending on what is happening in the cleanroom, different classifications are required. Internationally, the ISO classifications are used to determine the cleanliness of a cleanroom. There are 9 ISO classifications: ISO 1 defines the cleanest possible room and ISO 9 defines room air.

Why Does Cleanroom Classification Matter?

Your cleanroom classification identifies your cleanrooms as suitable for certain uses. Depending on your industry, a different governing organization might require or suggest certain classifications. In many industries, this is the Food and Drug Administration (FDA).

Even if you happen to be working in an industry that does not require classification, taking the time to understand how clean your cleanroom really is still important, the process behind cleanroom classification is an excellent way to determine if your contamination control strategy is working. It can also provide you with the confidence to know you are following best practices at all times.

How Does Cleanroom Classification Work?

To classify your cleanroom, you need to understand the cleanliness of every part of your cleanroom. There are four tests you will need to conduct:

- Airflow Volume/Velocity Readings: This test ensures the airflow is moving in the correct direction in the appropriate amount.

- HEPA Filter Integrity Testing: This is not required by ISO standards; however, it is mandatory with other organizations, like the FDA. This makes sure that your HEPA filter does not have any leaks.

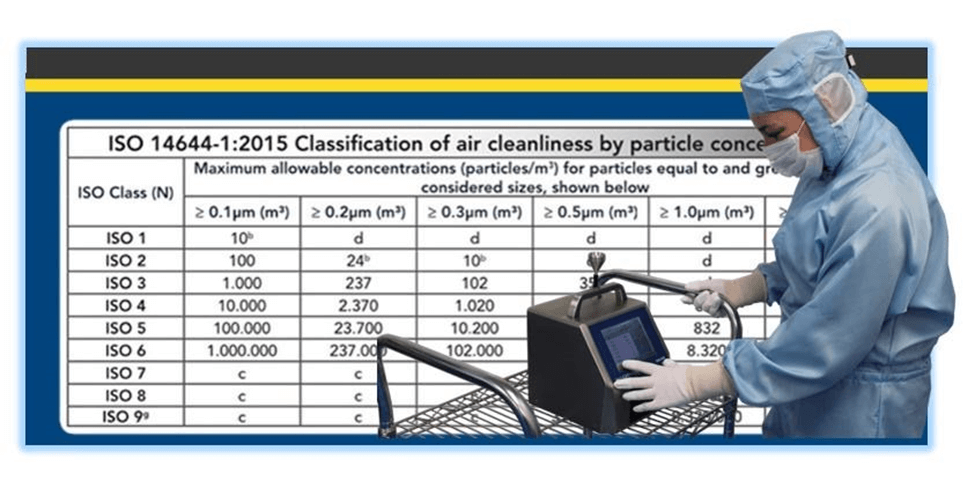

- Non-Viable Particle Counting: This is the test that actually determines how clean your cleanroom is. It tells you the number of particles in the measured area. It is what determines your cleanroom’s classification. If you need to measure viable particles, you will need to also use an air sampler instead of solely a particle counter.

- Room Pressurization Testing: Lastly, this test verifies that the room pressure is as desired.

Depending on the size and layout of your room, including the number of exits, you will have a certain amount of areas that require testing. You will need to take an average of the size and number of particles from every relevant portion of your cleanroom.

How Can You Ensure You Are Classifying Your Cleanroom Correctly?

Because you have to move around your cleanroom to measure, we often recommend the use of a portable particle counter. A permanent system of remote particles is a good way to constantly monitor a large cleanroom. But using a portable particle counter to assist in your classification allows you to test areas not typically tested.

To make the most of your verification, we suggest using a portable particle counter that…

- Has a built-in display so you don’t have to leave the room to see results.

- Allows for a number of integration options.

- Has a long battery life so you don’t have to stop in the middle of your classification.

- Gives readings lightning fast.

- Has the backing of a supplier who will calibrate and help maintain it.

- Recognizes particles down to at least 0.3 microns.

- Offers self-diagnostics, so you don’t get through the whole process then realize something was wrong.

The good news is that you don’t have to look far to find a portable particle counter that does all that. We offer all that – and more – in the ApexZ50.

But, more importantly, we want to empower you to make the best decision for your organization. That’s why we have a whole library of resources for free. With just a bit of studying every day in our Knowledge Center, you can be the expert on cleanrooms in every room. You can create a free account and get started making empowered, knowledgeable decisions today!