Keeping compressed gases clean and contaminant-free is a critical step in maintaining product quality and compliance, especially in sensitive industries like semiconductors and pharmaceuticals. Lighthouse Worldwide Solutions offers cutting-edge tools and support designed specifically for gas sampling and environmental monitoring—helping you meet stringent regulatory standards and protect your processes.

Comprehensive Particle and Microbial Monitoring

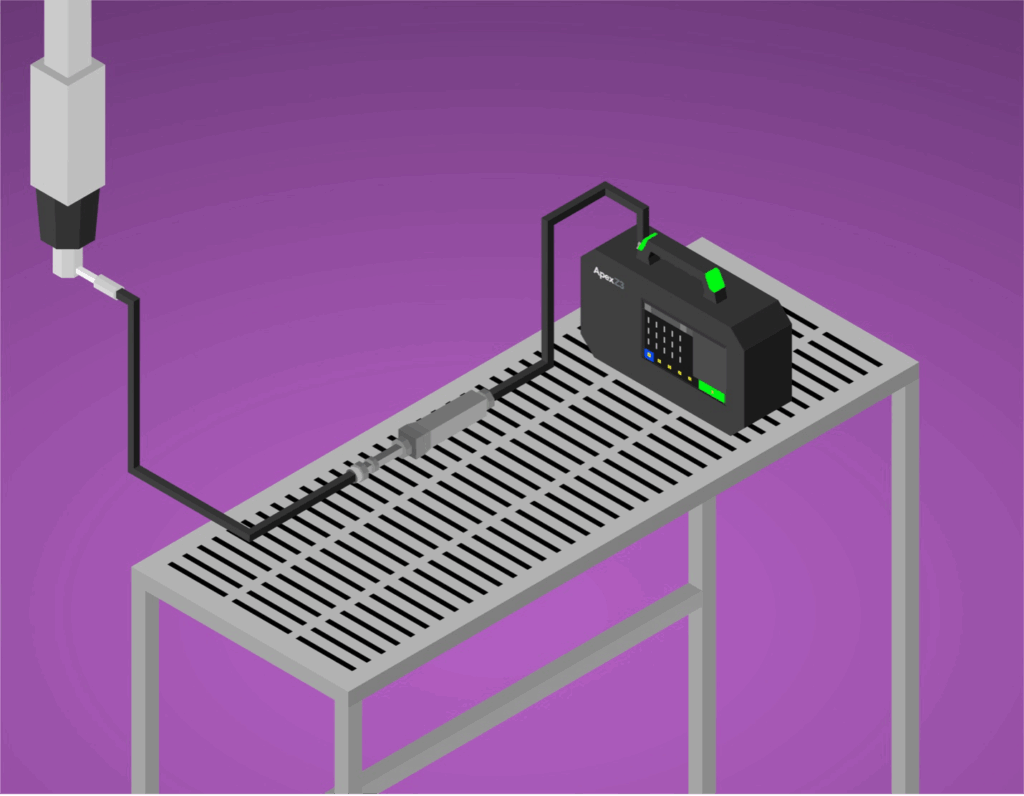

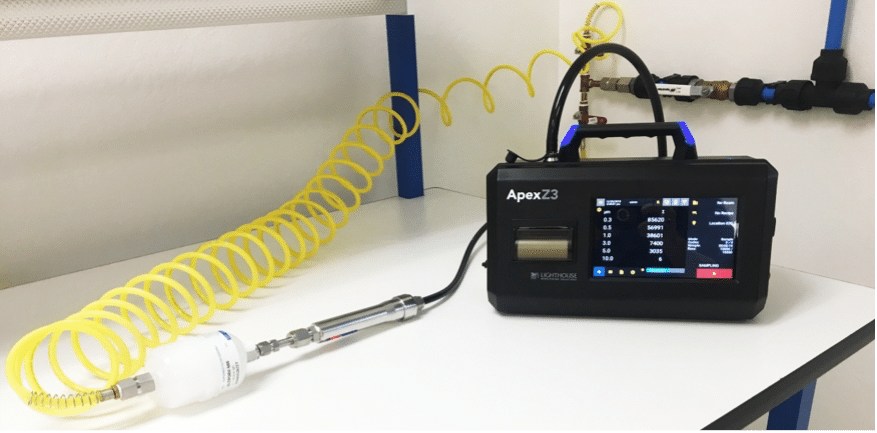

Lighthouse’s ApexZ Airborne Particle Counter is a state-of-the-art instrument capable of detecting particles down to 0.3 microns. When paired with specialized high-pressure diffusers, it allows safe, accurate sampling directly from pressurized gas lines, ensuring your gas feed into critical tools and processes is contaminant-free.

Our Solair 1100LD will take you down to 0.1 microns for processes where higher cleanliness is required such as in semiconductor, LCD and other sensitive applications.

Learn more about the Solair 1100LD here,

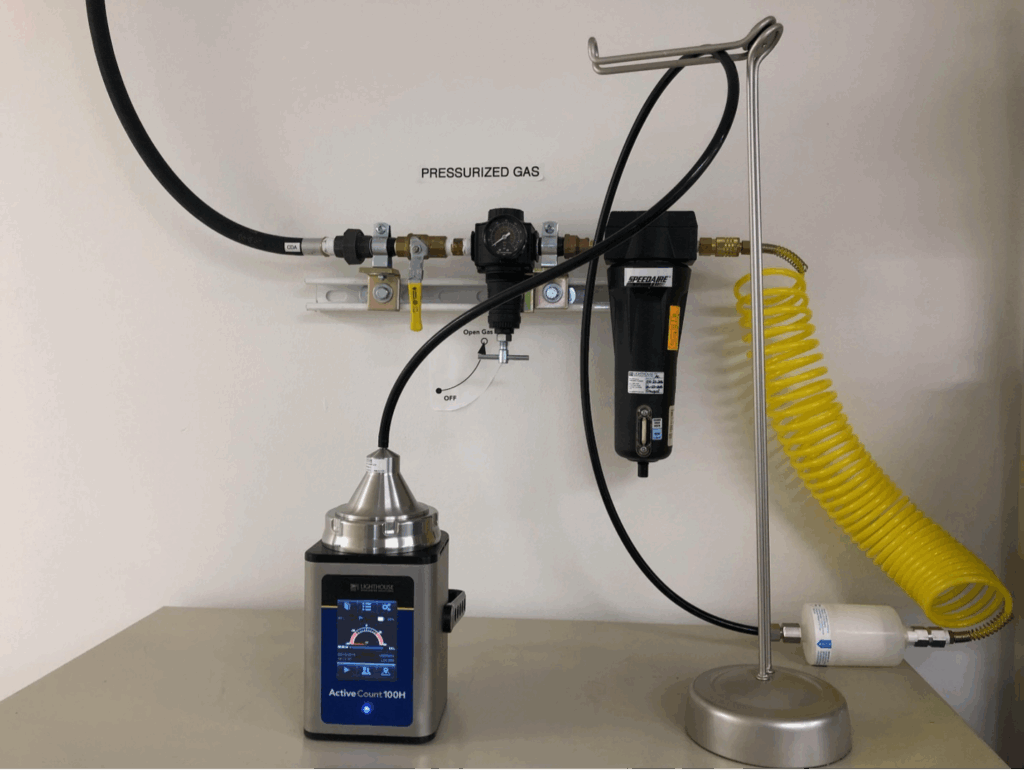

But contamination isn’t just about particles—microorganisms pose a serious risk, particularly in pharmaceutical cleanrooms. Lighthouse provides viable air samplers engineered to actively capture and monitor microbial contaminants in gases (Why viable air samplers matter). This ensures any microbial presence in your compressed air or gases is detected early, supporting patient safety and regulatory compliance.

Monitoring microorganisms is critical, particularly in pharmaceutical manufacturing. Lighthouse’s microbial sampling tools, such as the ActiveCount100H – are designed to capture any bacteria, molds, or fungi that could be lurking in your process gases. This helps you stay compliant with USP, EP, and cGMP regulations, which increasingly require microbial monitoring for gases used in cleanrooms.

Comprehensive Particle and Microbial Monitoring

Regulations like GMP Annex 1 (2022 update) and standards including ISO 8573 call for rigorous testing of compressed gases supplying cleanrooms (Gas sampling in biopharma cleanrooms). Lighthouse’s systems are designed to address these evolving requirements, providing audit-ready data with electronic signatures, audit trails, and secure data management compliant with 21 CFR Part 11.

"ISO 8573 is a multi-part international standard used to classify and measure the quality of compressed air by defining allowable limits for three major contaminants: particles, water, and oil, at any point in a compressed air system. ISO 8573 establishes standardized testing methods for compressed air quality, ensuring safety and efficiency in industrial, pharmaceutical, medical, and food production applications".

Simple, Flexible, and Connected Monitoring Solutions

Lighthouse’s monitoring solutions offer:

- Portability and ease of use, enabling you to sample gases from various points within your gas delivery and distribution system.

- Continuous data capture and remote monitoring, integrating with facility monitoring systems to provide real-time alerts if contamination thresholds are exceeded.

- Comprehensive training and expert support, helping you establish robust contamination control programs tailored to your facility’s unique risks and compliance needs (Basics of gas sampling in a cleanroom).

Why Choose Lighthouse?

With decades of experience supporting pharmaceutical and semiconductor industries worldwide, Lighthouse Worldwide Solutions combines innovative technology with expert consultation to help you build a contamination control program that’s reliable, repeatable, and compliant. Their solutions can help minimize costly recalls, production losses, and risks to patient safety or product integrity. See this link to book a consultation.

To explore our full suite of contamination control products and learn how they can help tailor your gas sampling approach, visit these Lighthouse Worldwide pages:

- Apex Z Particle Counter: https://www.golighthouse.com/en/airborne-particle-counters/apex-z/

- Why viable air samplers matter: https://www.golighthouse.com/en/blog/why-viable-air-samplers-are-important/

- Gas sampling in biopharma cleanrooms: https://www.golighthouse.com/en/blog/gas-sampling-in-biopharma-cleanrooms-ensuring-contamination-control/

- Basics of gas sampling in a cleanroom: https://www.golighthouse.com/en/blog/the-basics-of-gas-sampling-in-a-cleanroom-627/

- Webinar – Sampling Compressed Gasses in Cleanrooms: https://www.youtube.com/watch?v=ZXDC7myUD3c