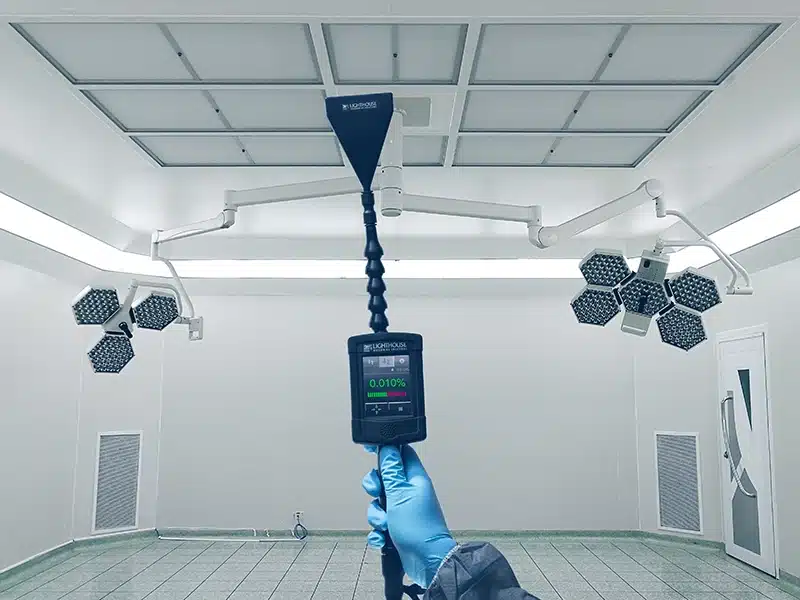

At Lighthouse Worldwide Solutions®, we don’t just build products: we build partnerships with the people who rely on them every day. That’s why the newest version of the ScanAir Pro is more than just an upgrade; it’s a direct response to the challenges faced by cleanroom professionals around the world.

After extensive feedback from customers and our global service network, we took a hard look at the original ScanAir Pro and asked ourselves: How can we make this even better? The answer: redesign key mechanical components for durability and test every detail to ensure lasting performance in real-world conditions.

Redesigned for Reliability:

Mechanical Improvements That Matter

In high-performance environments, even small flaws can lead to major downtime. Our service teams reported two recurring issues with the earlier ScanAir Pro model: inflexible tubing and breakage at the handle and nozzle connections. So we went back to the drawing board.

Separated Dual Tubing for Greater Flexibility

The long black dual tubing has been split into two independently routed lines. This separation reduces stiffness, allowing for better handling, improved maneuverability, and less user fatigue during extended use.

Removable Cable Management Clips

We added adjustable, removable clips to manage the newly separated tubing. This gives users more control over their setup while preventing tangles and snags during operation.

Strain Relief at the Handle Base

One of the most common failure points — the RJ45 connection at the handle — is now protected by a robust strain relief system. This enhancement absorbs stress from movement and extends the life of the internal cabling by preventing kinks and accidental breakage.

Push-Lock Nozzle with 360° Rotation

The nozzle connection has been completely redesigned with a push-lock fitting system that allows for free rotation. This not only makes the unit easier to use in tight spaces but also strengthens the joint and eliminates the need for glue — another former weak point.

Each of these changes was validated through flex testing, pull testing, leak testing, and zero count/particle trap testing. Bottom line: it’s been tested hard so you can trust it to perform.

Engineered with the End-User in Mind

From rugged mechanical upgrades to intelligent functionality, the new ScanAir Pro is designed to meet the needs of cleanroom professionals who can’t afford failure.

Whether you’re performing HEPA filter integrity tests, validating air systems, or monitoring critical environments, the ScanAir Pro delivers:

- Enhanced durability under repeated use

- Streamlined workflows with intuitive controls

- User-focused design that adapts to your environment

See the Difference for Yourself

We invite you to experience the new ScanAir Pro — a product shaped by feedback, engineered for performance, and built for the cleanrooms of today and tomorrow.

Interested in a demo or more details? Contact your local Lighthouse representative or visit our website to learn more.