We talk a lot about contamination control strategies in a cleanroom, but there is another type of strategy you need to consider: air distribution. This strategy is typically put into place during the planning and building of a cleanroom because it has a lot to do with infrastructure. But understanding your cleanroom’s air distribution strategy will give you a better understanding of your cleanroom’s overall environment.

Why Does Air Distribution Matter

Air distribution does a few things in your cleanroom.

First and foremost, it directs the flow of the air in your cleanroom.

A proper cleanroom air distribution strategy makes ample use of laminar air flow (or unidirectional air flow).

This forces particles to move with the flow of the air, quickly being directed through the appropriate HEPA and ULPA filters, limiting your cleanroom’s exposure to contamination. Your strategy should also account for a worse cast scenario: turbulent air flow, when air mixes with the room without any laminar flow. Ideally, though, all entry points for air would be accounted for and laminar air flow achieved.

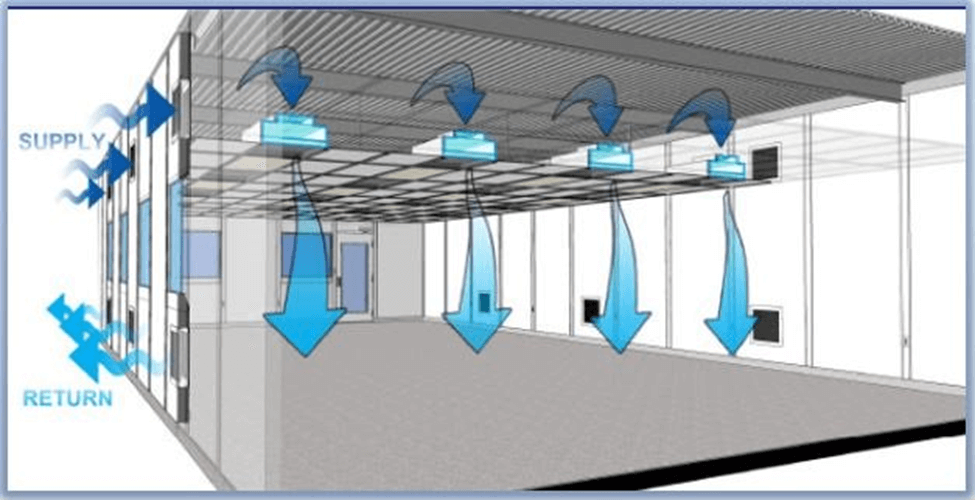

Second, proper air distribution helps control the temperature of your cleanroom. A cleanroom should be kept at a crisp 21°C for most applications. An occasional variance of 2°C is acceptable in some industries. Many cleanrooms use a low-level air return system to help achieve laminar air flow and even temperatures. This means that air is returned from the top of the room to the bottom. Since hot air rises and cold air sinks, this combination of the air helps to maintain an even temperature.

Third, proper air distribution helps protect personnel from prolonged exposure to potentially hazardous chemicals. We all know that cleanrooms are highly controlled spaces for a reason. Most of the time, it is to protect the product from outside contamination. Many times, though, especially in the pharmaceutical and research spaces, the cleanroom serves the purpose of also protecting the personnel. Ideal cleanroom air distribution quickly removes and filters air to protect both the product and the personnel.

Creating Laminar Air Flow

As we mentioned before, including low-level returns in your cleanroom is an excellent way to create laminar air flow and aid in your cleanroom’s temperature maintenance. But what else should you consider when attempting to create laminar air flow?

Cleanrooms are either positive or negative pressure environments. This means that their air pressure is either higher or lower than the outside environment, which also creates air flow.

If a cleanroom is a positive pressure environment, air will rush out of the room when a seal is broken, such as when personnel enter the room. This is used when cross-contamination is a serious risk.

On the other hand, if a cleanroom is a negative pressure room, air will rush into the space when a seal is broken. Negative pressure is used when the contents of the room are a danger to outside spaces, such as in quarantine units in hospitals and certain pharmaceutical applications.

When developing your cleanroom air distribution strategy, this is important to consider. It is also possible to create negative pressure in the direction in which you wish to create laminar air flow using fans and vacuums.

How Do You Know Your Cleanroom Air Distribution Strategy Is Working

There will be a few tall tale signs that your cleanroom air distribution strategy is actually working.

On the surface, you will be able to see, feel, and hear it. You should hear the sounds of creating air movement: a sort of wind tunnel effect. You should also feel the air moving and note any air direction signals you have up moving. The cleanroom’s temperature should also stay consistent.

At a micro level, you should see little to no contamination. You will need to use a particle counter system (which you should be using anyway for constant monitoring) to note your levels of contamination. If you use a portable particle counter, you can check certain areas to see if there are higher levels of contamination in one spot over another. If you are noting higher levels of contamination in one spot, you should start a series of diagnostics. You can start by asking yourself basic questions:

- Who is working in this space? (Humans are responsible for 75-80% of particle contamination in a cleanroom. It might just be time for gowning protocol updates!)

- What is happening in this space?

- Is there something that would block proper airflow around this area?

If these don’t present an obvious solution, you will need to dive deeper based on your cleanroom’s application.

Lastly, if your cleanroom air distribution strategy is working correctly, your personnel should be protected. If personnel start to consistently exhibit signs of overexposure to the hazardous materials in your cleanroom, you should:

- Conduct gowning protocol training,

- Check your PPE supplier for any recalls or concerns with the PPE itself,

- And make sure your airflow is still moving at an appropriate rate to protect your personnel.

Your air distribution strategy is an important part of your cleanroom! We all want to protect your application and your personnel.

Thus, it is definitely one you want to understand thoroughly.

If there is more about your cleanroom that you want a better understanding of, check out our Knowledge Center. This is a compilation of everything we have learned as the world’s clean air experts for over 40 years! And it is totally free.

We break down the complex topics, guidelines, and legislation around cleanrooms and contamination control into easy-to-understand content.