In highly regulated industries such as pharmaceuticals, biotechnology, and advanced manufacturing, contamination control is non-negotiable. Airborne particle monitoring plays a central role in ensuring cleanroom environments meet strict regulatory requirements like EU GMP Annex 1: 2022 and ISO 14644. One of the most effective tools for achieving continuous, reliable oversight is remote sampling.

But what exactly is remote sampling, how does it work, and why is it so widely used? Let’s break down the basics…

What is Remote Sampling?

Remote sampling refers to the use of fixed-point particle counters connected to tubing that continuously draws air from a defined location to the instrument. Unlike portable counters, which are manually moved around, remote airborne particle counters (APCs) stay installed in place and provide real-time monitoring at critical points in the cleanroom or within equipment such as:

- Isolators – fully enclosed systems that separate operators from products.

- Biological Safety Cabinets (BSCs) – airflow-controlled enclosures that protect operators, products, and environments from cross-contamination.

- Laminar Flow Benches (LAFs) – workstations that deliver clean, unidirectional airflow to protect sensitive products.

- Filling lines – where vials or ampoules are filled along an automated filling line.

By continuously sampling these areas, facilities can detect deviations immediately, rather than relying only on periodic manual tests.

Why Remote Sampling Matters

Remote sampling solves several challenges faced by cleanroom operators:

- Continuous Oversight – Portable counters provide snapshots, but remote APCs ensure uninterrupted monitoring, essential for ISO 5/7 and Grade A/B environments.

- Faster Response – With alarm notifications integrated into Facility Monitoring Systems (FMS), operators can take action as soon as contamination levels begin to rise.

- Compliance Confidence – Regulators expect continuous monitoring in critical zones. Remote systems meet these expectations with built-in data logging and traceability.

- Reduced Human Error – Automated monitoring reduces reliance on operator presence, limiting disruptions and the potential for contamination during manual sampling.

How Remote Sampling Works

- Sampling Point Placement

Probes are positioned in high-risk zones, determined by risk assessment—such as filling lines, stopper bowls, or where aseptic connections are carried out. Correct placement ensures meaningful, representative data. - Tubing and Flow Control

Air is drawn through tubing to the particle counter. Careful design prevents losses from long tubing runs, bends, or flow disruption. Standards like ISO/TR 14644-21 guide best practices for minimizing particle loss during transport. - Real-Time Counting

Remote counters measure airborne particles (typically ≥0.5 µm and ≥5.0 µm) against cleanroom limits. This data is continuously streamed to monitoring software. - Data Integration & Alerts

Results feed into a Facility Monitoring System (FMS), which provides dashboards, trending, and automatic alerts when limits are exceeded. These logs also serve as audit-ready records for GMP compliance.

Key Considerations for Remote Sampling

When planning a remote monitoring setup, facilities should keep in mind:

- Calibration – Remote counters must be calibrated to ISO 21501-4 to ensure accuracy, repeatability and reliability of the data.

- Isokinetic Sampling – Probes should be designed to match airflow velocity, ensuring representative particle collection and face upwards towards the HEPA filtered air passing over the sterile process.

- Validation – Proper validation (IQ/OQ) confirms the system’s performance under real operating conditions along with a robust PQ before handover.

- Maintenance – Routine checks and preventive maintenance keep systems accurate and reliable long-term.

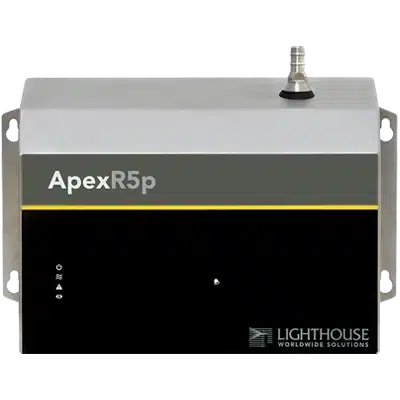

Remote Particle Counters from LWS

Lighthouse offers a full line of remote airborne particle counters built for regulated cleanroom environments. With models available in multiple flow rates (0.1 CFM and 1.0 CFM), these counters are:

- Calibrated to ISO 21501-4 and ISO 17025 for accuracy and consistency

- Designed for seamless integration with Lighthouse’s Monitoring Systems (LMS)

- Proven durable in demanding applications across pharma, biotech, semiconductor, and aerospace industries with it cleanroom friendly design and enclosure seals.

- Supported globally with calibration, service, and compliance expertise

- Eliminates operator handling with Smart Bracket Technology where the sample ID is fixed to the location and not the remote particle counter.

- Built in WiFi communications for on the spot diagnosis and data inquires via tablet device

Explore our Remote Particle Counters with built in Pumps

Explore our Remote Particle Counters that use your house vacuum system

The Bottom Line...

Remote sampling is the backbone of modern cleanroom environmental monitoring. By providing continuous, automated, and compliant particle measurement, it allows facilities to stay ahead of risks, protect product quality, and satisfy regulators.

For pharmaceutical, biotech, and semiconductor manufacturers, mastering the basics of remote sampling isn’t just about compliance — it’s about ensuring the safety, reliability, and efficiency of every operation.